Can Table Salt Save the Energy Storage Industry? Experts Consider Sodium-Ion Batteries a Viable Alternative to Lithium-Ion

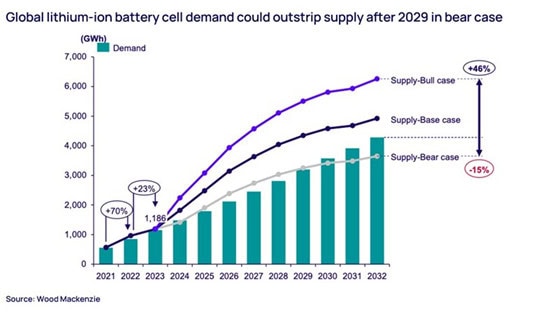

The most prevalent type of battery on the market today is lithium-ion. These batteries are used in cell phones, laptops, electric vehicles, and in both residential and grid-scale energy storage installations. Projections show that by 2029, demand for lithium-ion batteries will outpace the global supply of lithium. A recent webinar hosted by the Energy Storage Technology Advancement Partnership (ESTAP) brought together experts from national laboratories and the battery storage industry for a discussion on viable alternatives to lithium-ion, such as sodium-ion.

In his opening remarks, Dr. Imre Gyuk, Chief Scientist at the U.S. Department of Energy, Office of Electricity, explained the urgent need for earth-abundant, domestically available, inexpensive materials to create batteries that have performance characteristics similar to lithium-ion. The fast-growing electric vehicle industry will soon require all available lithium, leaving stationary battery manufacturers without a critical component for their product.

Source: Wood Mackenzie

Sodium-ion batteries are a leading contender to replace lithium-ion batteries because the raw materials are both cheaper and globally available. Lithium carbonate, the raw material for lithium batteries, costs roughly $20,000/ton. Sodium carbonate, on the other hand, costs $332/ton. “Sodium-ion batteries lag lithium-ion with respect to performance, but they are competitive on price and can be sourced domestically,” said Dr. Gyuk. “I am confident that they will find their market when lithium becomes scarce.”

Ramesh Koripella, materials scientist and engineer at Sandia National Laboratories, highlighted the safety benefits of sodium-ion batteries. Unlike lithium-ion batteries, they don’t present significant problems with thermal runaway, which can lead to fires. They also can be transported and shipped in a zero-charge state, which reduces risks associated with transporting batteries.

As for performance, sodium batteries have long life cycles and can perform hundreds of partial discharges per day to manage peak loads. They can also perform many of the other services currently provided by lithium-ion batteries, such as supporting microgrids and grid stabilization, and providing black start capabilities.

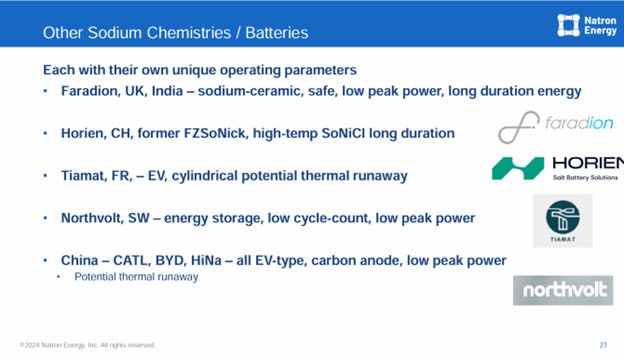

However, not all types of sodium batteries are equal. Koripella distinguishes between the lower temperature sodium-ion batteries, which are comparable to lithium-ion batteries and already in commercial production, and the higher temperature “molten sodium batteries,” which are largely still in the research and development phase, with few commercially available. Both high- and low-temperature sodium batteries come in several different varieties.

A frequently expressed concern about lithium-ion batteries is safety. So, are sodium-ion batteries safer? Sandia National Laboratories’ Battery Abuse Testing Lab puts commercial batteries through various forms of abuse including nail penetrations, overcharge, over-discharge, and other less-common potential hazard situations, such as laser-initiation of runaway. Sandia also has a bunker in a remote desert area that serves as their burn-site testing facility, where larger-scale batteries are set ablaze, and data is collected about fire propagation rate and thermal runaway. Alex Bates, a Sandia scientist studying sodium-ion battery safety, described and showed videos of various safety tests on both lithium- and sodium-ion batteries. Some of the results are compiled in the table below.

Source: Sandia National Laboratories, Lorraine Torres-Castro, Alex Bates

“Not all sodium-batteries are equal,” Bates emphasized; some types may be safer than others when subjected to various forms of abuse.

US-based battery manufacturer Natron Energy has recently opened a commercial sodium-ion battery factory in Holland, MI. Their primary product is Prussian blue analog sodium-ion batteries. Jack Pouchet, VP of Sales for Natron Energy, described them as eliminating many issues typical of lithium-ion batteries: they have a higher cycle rate, are not subject to thermal runaway, can be shipped fully charged (which allows them to be more quickly transported and installed), and do not require materials from industries plagued with environmental and human rights abuse issues such as lithium, cobalt, nickel, copper and zinc. They also have a wider operating range of temperature, which reduces the need for temperature control for the battery environment. They’re less energy dense, meaning their footprint is larger per kW, but this is less critical for stationary applications than for EVs.

Natron Energy’s battery plant in Michigan is qualified for Build America Buy America (BABA) and other Buy American Acts, and the raw materials for these batteries are being sourced in the United States, according to Pouchet. He also stated that, “with most designs of sodium-ion technologies, you can put these into a lithium-ion factory. So, you’re not reinventing the wheel or creating a new framework from a manufacturing perspective.”

Of course, Natron Energy is not the only manufacturer of sodium-ion batteries, with other producers springing up in China, India and Europe.

Source: Natron Energy, Inc.

So – will table salt save the energy storage industry?

Not exactly, says Dr. Gyuk. “Sodium carbonate is not table salt. Table salt is sodium chloride, which is a different thing altogether.” But, while we can’t count on table salt to save us, sodium-ion batteries, which rely on another earth-abundant salt, certainly have potential.

Published On

January 2, 2025